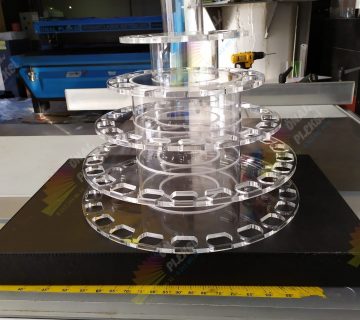

Acrylic

Plexi, plastic glass with colored and colorless varieties. Transparent and semi-transparent. Easily processed, it can be perforated can be cut, a light plastic structure.

Acrylic

It is generally found in the market as flat sheets with a thickness of 1.5-2 5mm. It is softened by heating in an oven at 90°C or 90°C – 115°C. Thus, the desired shape can be given by molding. It is more durable and lighter than glass. Its only disadvantage is that it has a thermodynamic structure, so its resistance to burning is less. (Casting) Plexiglas allows it to be applied to any desired shape easily. It does not leave Plexiglas users in a difficult situation during the manufacturing phase. Plexiglass extruder does not cause problems in cutting, inflation and shaping like sheets. Its technical features such as expansion coefficient, density, softening point, hardness are in accordance with the standards and the number of polymers is high.

Plexi Features

- High light transmittance and light transmittance is 92% shock resistant than glass. The impact resistance of glass is more than 6 times. Sharp edges are not. not cause injuries. Thermal conductivity of the glass is less than 20%.

- (Casting) is resistant to climatic conditions Plexiglas, transparent and produced in fluorescent colors and more resistant to climate conditions compared to plastic. Solmaz unbreakable. easily used indoors and outdoors.

- (Casting) dayanıklıdır.dök according to the Plexiglas Plexiglas heat softens thick as 75 ° C and is ready to give way.

- Acrylic (Cast) copper hardness is Plexiglas.

- to enter the desired form plexiglass form which is easily verilir.isten Alglas Pleksi'ye just 120 ° -150 ° C. After cooling to form remains constant.